Absorption Chiller

February 3, 2024

Exhaust Gas Boiler

February 3, 2024

Air Cooled Electric Chiller

Water Cooled Electric Chiller

Advantages

Features

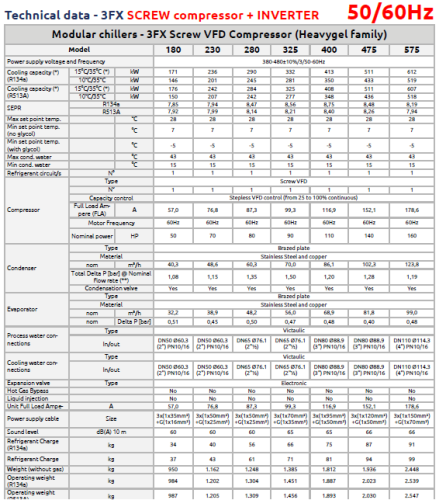

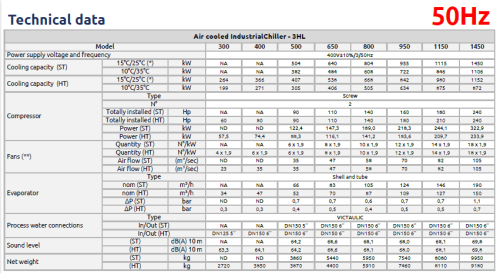

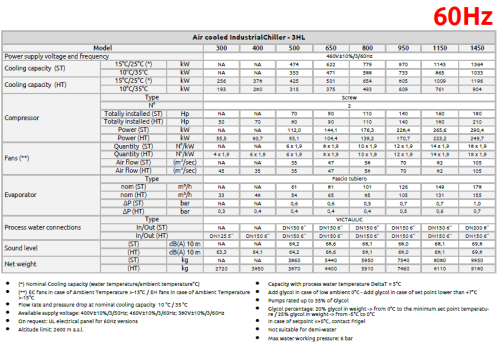

Detailed Specifications

Main Features

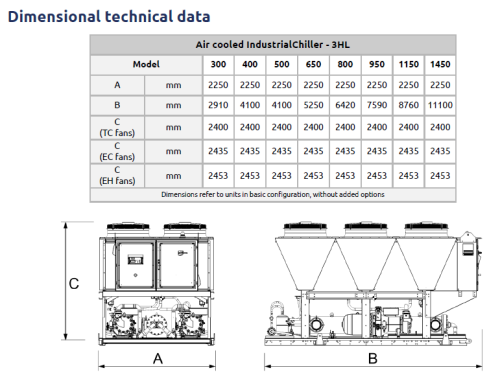

• 3 fans configurations:

• TC: fans with phase cut speed control

• EC: brushless variable speed fans

• EH: high pressure fans, suitable for ducting in-door installation

• High efficiency screw compressors

• Shell and tube evaporator

• Copper condenser with aluminium plates

• Microprocessor temperature controller with touch screen interface and serial connection to 3PR remote control panel

• Electronic thermostatic valves

• Hydraulic configuration: without pumps and tank (N).

Technical features

Screw compressors:

• Semi-hermetic screw compressors, BITZER;

• electronic protection;

• integrated oil separator;

• differential pressure lubrication system;

• oil filter;

• oil level safety device;

• crankcase heater;

• refrigerant R134a;

• high and low pressure gauges and pressure switches;

• continuous proportional control (25/100%).

Condenser

• Higher efficiency and performances

• mechanically expanded copper tubes in collar, spaced by alumi-nium fins with very low internal volume, "V-shape" arrangement;

• special integrated sub-cooling circuit.

Axial fans

• TC: fans with phase cut speed control

• TRIAC speed regulation;

• fan speed continuous adjustment with consequent condenser cooling air flow regulation;

• correct pressure in the refrigerant circuit guaranteed even at low winter temperatures.

• EC: brushless variable speed fans:

• high efficiency, improved reliability and durability;

• integrated electronics;

• 100% adjustable speed;

• consumption reduced by more than 30%;

• low noise emissions (less than 57dB(A));

• complies with the strictest EMC regulations.

• EH: high head EC fans

• suitable for ducting on indoor installations (heat recovery) ;

• for ambient temperatures greater than –15 °C.

Shell and tube evaporator

• Optimised for use with R134a refrigerant;

• copper tubes with high exchange surface area

• thermal insulation;

• water differential pressure switch;

• water circuit drain;

• air vent valves and hydraulic connections conveyed to the outside with VICTAULIC elastic joint or flanged adapter.

Systems

Modularity

Allows to easily build large systems, rating cooling capaci-ties from 100 to 3.500 kW.

Configurations

There are two main system configurations:

• Modular Central Cooling Systems: units connected in parallel designed to add capacity as the thermal loads increase;

• MultiStage Cascade Cooling Systems: units connected in series designed for cascade cooling.

Heat pump

For both system configurations a Heat-Pump optional feature is available.

Accessories

In both parallel and cascade configurations, are inte-grated with a full variety of accessories, such as modular recirculating and process pumping stations, stainless steel tanks, filtration systems and a remote control sys-tem that automatically manages capacity control, energy consumption optimization, working hour equalization, alarms and all operating parameters.